HOME

SHOP

1933 DODGE COUPE

FRONT SUSPENSION

.

Alright I have made a decision. This car will have a straight front axle. Some people refer to them as solid. The magazine guys always talk about Mustang II stuff and how it handles so much better. 1st if I remember correctly those Mustang IIs were cheap wanna be cars. The steering geometery isn't all that good any way. 2nd every 4X4 I have owned has had a straight front axle, and I don't recall any of them being horrendous to drive. So I have an original Dodge tube axle and a 55 Chev I beam axle. I guess I will have to see what fits my plan better.

If you really wanted a car that handled you would not be building old coupes any way, their center of gravity is quite high. Again if you really wanted an IFS that handled you would figure out how to install a 70 and up Camaro/Firebird front end.

I think the only real advantage to the Mustang II is going to be ride quality, other than availability. Straight axles and leaf springs tend to have a stiff ride. The shorter the leaf spring the harsher it will ride, all old cars have short leafs (except Ford buggy springs).

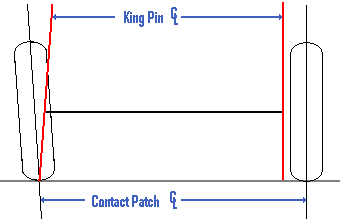

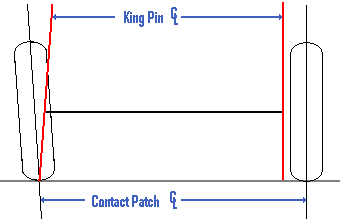

The biggest thing is finding an axle that has kingpin inclination (Timkin center point steering). This is when a line through the kingpin intersects the ground at the center of the tire contact patch. Old straight axles had vertical kingpins, so the tire has to scrub when you turn. In the drawing to the right the red line represents king pin inclination. The object would be to have that red line and the line through the center wheel plane meet at the surface of the ground. That would give the most effortless steering, and the least bump steer. Notice the leverage difference that a bump will have on these 2 different axle set ups. The inclined king pin will have much less tendency to rotate around the king pin when the tire hits a bump. This will result in much less bump steer than the old 1930s style geometry. In the diagram, the left side represents the more modern geometry, and the right side is your basic farm implement or 1930s design.

However after you spent all this time getting "Timkin Center Point" steering you would probably buy a set of offset wheels that would negate all your hard work.

The biggest thing is finding an axle that has kingpin inclination (Timkin center point steering). This is when a line through the kingpin intersects the ground at the center of the tire contact patch. Old straight axles had vertical kingpins, so the tire has to scrub when you turn. In the drawing to the right the red line represents king pin inclination. The object would be to have that red line and the line through the center wheel plane meet at the surface of the ground. That would give the most effortless steering, and the least bump steer. Notice the leverage difference that a bump will have on these 2 different axle set ups. The inclined king pin will have much less tendency to rotate around the king pin when the tire hits a bump. This will result in much less bump steer than the old 1930s style geometry. In the diagram, the left side represents the more modern geometry, and the right side is your basic farm implement or 1930s design.

However after you spent all this time getting "Timkin Center Point" steering you would probably buy a set of offset wheels that would negate all your hard work.

If I use coil overs and radius rods It should have a decent ride. I will have to study unequal length radius rod geometry to see if there is any advantage, such as anti-dive during braking.

The front suspension will consist of a straight axle and coilover shocks. I am going to use parallel(?) radius rods. I am going to make them unequal length. At a neutral ride height the car will have x amount of caster, with any amount of travel in either the up or down direction the caster will increase slightly.

As for an axle, I have fabbed one from leftovers from my 4X days. I imagine it is kind of over kill but it certainly was cheap. I took a 4X front axle and removed the housing ends. Then I installed them onto a piece of 2.750" O.D. tubing. These ends need to be perfectly aligned from side to side.

I have a neat trick for the radius rods too. I have some 1.25" tubing with .090" wall. I was going to make a weld in thread adapter, but a left hand tap was pricey. So I looked around and remembered that semis (big rigs or 18 wheelers or whatever) have 3/4" wheel studs in both right and left threads. I machined the threads from the outside, of a dual lug nut, and got a press fit into the tubes. I left a bit of thread near the shoulder of the RH and trimmed a regular lug nut so there would be an adjuster.

HOME

Free Hit Counter

The biggest thing is finding an axle that has kingpin inclination (Timkin center point steering). This is when a line through the kingpin intersects the ground at the center of the tire contact patch. Old straight axles had vertical kingpins, so the tire has to scrub when you turn. In the drawing to the right the red line represents king pin inclination. The object would be to have that red line and the line through the center wheel plane meet at the surface of the ground. That would give the most effortless steering, and the least bump steer. Notice the leverage difference that a bump will have on these 2 different axle set ups. The inclined king pin will have much less tendency to rotate around the king pin when the tire hits a bump. This will result in much less bump steer than the old 1930s style geometry. In the diagram, the left side represents the more modern geometry, and the right side is your basic farm implement or 1930s design.

However after you spent all this time getting "Timkin Center Point" steering you would probably buy a set of offset wheels that would negate all your hard work.

The biggest thing is finding an axle that has kingpin inclination (Timkin center point steering). This is when a line through the kingpin intersects the ground at the center of the tire contact patch. Old straight axles had vertical kingpins, so the tire has to scrub when you turn. In the drawing to the right the red line represents king pin inclination. The object would be to have that red line and the line through the center wheel plane meet at the surface of the ground. That would give the most effortless steering, and the least bump steer. Notice the leverage difference that a bump will have on these 2 different axle set ups. The inclined king pin will have much less tendency to rotate around the king pin when the tire hits a bump. This will result in much less bump steer than the old 1930s style geometry. In the diagram, the left side represents the more modern geometry, and the right side is your basic farm implement or 1930s design.

However after you spent all this time getting "Timkin Center Point" steering you would probably buy a set of offset wheels that would negate all your hard work.