3 CYLINDER

page counter

3 CYLINDER | page counter |

You can see some additional information on the Crank Shop web page.

While this was listed on eBay I researched the piston cituation. There is a thin area of the casting near the water jacket. The engine can be built to 80mm bore safely, the 84mm bore will remove too much metal. There are 3 bore sizes that work out better than the others, 67.9mm, 695cc; 72mm, 780cc; 80mm, 965cc. Factory Rotax sleeves should be available for the 72mm, 521 Ski-Doo; and 80mm bores, 320 Can-Am or SWM, that match the 64mm stroke, and 5 transfer layout. You would still need to cut in exhaust boosters. The 76mm, 583 Ski-Doo sleeve is too small, for the 670 cylinder, and the adapter sleeve would be too thin. The 72mm pistons are probably still easy to purchase, the 320 Can-Am piston might be difficult to locate.

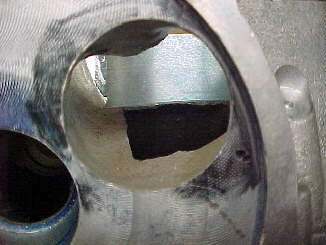

These 2 photos are mock ups, You choose the bore size and make it what you want. Just remember it has 18mm wrist pins. You should machine the tops off the 670 jugs so the transfers match the 583 height-- You don't want to raise the top of the transfer port-- that robs top end, but does help low end power. You can live with the higher exhaust. If you end up with transfers to high you can shorten the head pipe to bring back some of the top end. My plan was to use Formula III race pipes at 9200 RPM. I would also tend toward long intake duration something like 179° opening and 85° closing.

These 2 photos are mock ups, You choose the bore size and make it what you want. Just remember it has 18mm wrist pins. You should machine the tops off the 670 jugs so the transfers match the 583 height-- You don't want to raise the top of the transfer port-- that robs top end, but does help low end power. You can live with the higher exhaust. If you end up with transfers to high you can shorten the head pipe to bring back some of the top end. My plan was to use Formula III race pipes at 9200 RPM. I would also tend toward long intake duration something like 179° opening and 85° closing. Those 320 Can-Am sleeves and pistons would make it pretty slick. The ports would probably match up quite well, the early Can-Ams have 4 transfers + the rear boost transfer just like the Ski-Doo. I see SWM used a Rotax 320 from 1978-1982, it is based on the 250MX, so it should have the 18mm wrist pins.It only has the single exhaust so you would have to drill in the 2 side boost exhaust. The other modificaion would be cutting the o-ring groove in the flange. Probably should check availability of these out of production pieces, before commiting. The 521 and 583 sleeves would match the stroke but need a special thick sleeve or an adapter sleeve. I had contacted Northwest Sleeve in Gresham OR, and L.A. Sleeve years ago and they would both make custom (thick) sleeves, but the price was like double or triple stock sleeves. Superior Sleeve might be a source. I also asked about blank sleeves with no port windows, just a flanged top, they were cheap as I recall. It would take a bit of time to cut the ports in though.

WOW That 370/400-406 piston looks pretty nice too. A set of 370 sleeves might work reasonably well also. The BOTTOM of the port windows would be 1mm lower than needed, and that won't hurt anything. This combo would certainly use those big transfers. Remember this engine is at least 33% larger than it was as a 583, it will have a correspondingly large mid-range power boost.

The POLAR crankcases cost $1500.00. The Crank Shop sells a case like this for $2100.00. These cases have never been assembled,

they are NEW. They are .400" taller than stock, to make room for the 120°

intake spacing. You can visit my

porting page to see the advantages of the rotary valve over the reed valve. The bore size would be easiest to go to a big bore set. If you choose a smaller bore you will have to make an aluminum sleeve to adapt the "stock" iron sleeve.

The POLAR crankcases cost $1500.00. The Crank Shop sells a case like this for $2100.00. These cases have never been assembled,

they are NEW. They are .400" taller than stock, to make room for the 120°

intake spacing. You can visit my

porting page to see the advantages of the rotary valve over the reed valve. The bore size would be easiest to go to a big bore set. If you choose a smaller bore you will have to make an aluminum sleeve to adapt the "stock" iron sleeve. Looking at the case in these photos I wonder how much it can safely be bored. The wall in the upper right corner between the water jacket and the cylinder spigot is kind of thin, 3/16". The spigot hole is 85mm diameter, stock 670 size ............Probably can only sneek in about the 80mm bore safely, maybe the 84mm. For the 84mm bore that thin spot is going to be 3/32" wide, not much gasket surface or crack resistance. So the 965cc is about the limit with the 64mm stroke. The 72mm, 76mm, and 84mm pistons probably have the best availability.

On a 2 cylinder the ports are 180° apart, on a horizontal

line. To get the 120° spacing the ports are squeezed toward each other at

the top. This necessitates a taller case and a shorter cylinder. After

determining where you want the port timing remove metal from the cylinder

bottoms. Then you need to have .045" from the top of the piston ring to

the top of the cylinder "deck height" so you remove the material to make

that happen.

On a 2 cylinder the ports are 180° apart, on a horizontal

line. To get the 120° spacing the ports are squeezed toward each other at

the top. This necessitates a taller case and a shorter cylinder. After

determining where you want the port timing remove metal from the cylinder

bottoms. Then you need to have .045" from the top of the piston ring to

the top of the cylinder "deck height" so you remove the material to make

that happen.

These next 2 pictures show the proximity of the ports to the RV edge. The

distance is roughly 1/8".

These next 2 pictures show the proximity of the ports to the RV edge. The

distance is roughly 1/8".Some people are concerned with this dimension, but just like the 2 bangers it can have a brass wear plate added if it wears. If you want the biggest of carbs , check out these Crank Shop monsters. To use the big carbs you should put in the brass R/V wear plate , because the port needs to be opened up a bunch.

Why don't the 2 stroke guys use a plenum chamber? On a 4 stroke when you run IR (individual runner) intake it requires a bigger carb. The comparison is a Holley 1150cfm Dominator vs a 660cfm on a tunnel ram. So if I make a plenum that allows an intake port to pull from multiple carbs couldn't I use smaller carbs. Say 3 40mm (cheap Ski-doo take-offs) vs those carb shop 52mm jobbies. Another problem area, the intake needs to flow 10%-15% more than the exhaust. So if you have a 1.75 exhaust, which is 44mm, shouldn't you have something close to 50mm for an intake tract. Don't the Banshee guys have a roost boost bottle that does the same thing as a plenum. OK I have brass plate to make the wear plates...so.

Left, POLAR supplies an RV cover machined from flat plate.

Left, POLAR supplies an RV cover machined from flat plate. Right,

the extra, semi finised RV cover. This is what they both looked like when

they arrived.

The crankshaft has been assembled. The 583 connecting rods have 18mm wrist pins. I see The Crank Shop sells a billet crank for $2800.00

The crankshaft has been assembled. The 583 connecting rods have 18mm wrist pins. I see The Crank Shop sells a billet crank for $2800.00

Right, there is $450.00 worth of NEW rebuild parts in the crank.

3 NEW 583 connecting rods, ALL the NEW bearings and seals.

The assembled a crank. Since it didn't sell, I guess I will try to add brass Rotary Valve wear plates, and get the tunnel porting finished, so I can assemble the bottom end. I should also cut the cylinder tops down, but I can't cut the cylinder bottoms until a piston choice is made.

Of course the price will go up to reflect the time, and money invested.

The assembled a crank. Since it didn't sell, I guess I will try to add brass Rotary Valve wear plates, and get the tunnel porting finished, so I can assemble the bottom end. I should also cut the cylinder tops down, but I can't cut the cylinder bottoms until a piston choice is made.

Of course the price will go up to reflect the time, and money invested.

The head is made from 2- 670 heads welded together. This head has been surfaced, but will need more machining to achieve the compression ratio desired. If I end up building this maybe I'll do chamber inserts for adjustable compression. One thing I noticed over time...before I milled heads, none of the ported engines I made ever blew up. Compression was rarely above 110lbs. Once I started to cut heads, and pushed the compression to 140-150 (175 once) the life expectancy dropped right off. The car guys learned to make more power with timing and air flow than compression (11.5:1 in the 70s now its 9.5:1)

Union Bay head inserts , click on billet cheater head, the picture is a Polaris part, but you get the idea.

The head is made from 2- 670 heads welded together. This head has been surfaced, but will need more machining to achieve the compression ratio desired. If I end up building this maybe I'll do chamber inserts for adjustable compression. One thing I noticed over time...before I milled heads, none of the ported engines I made ever blew up. Compression was rarely above 110lbs. Once I started to cut heads, and pushed the compression to 140-150 (175 once) the life expectancy dropped right off. The car guys learned to make more power with timing and air flow than compression (11.5:1 in the 70s now its 9.5:1)

Union Bay head inserts , click on billet cheater head, the picture is a Polaris part, but you get the idea.

Left,

2 RV shaft assemblies with water pump impellers.

Left,

2 RV shaft assemblies with water pump impellers. Right, 3 NEW boots for 44mm Mikuni carbs. I am also shipping 3 exhaust flanges.

Left, gaskets, seals and o-rings

Left, gaskets, seals and o-ringsRight, fuel pump made by sandwiching 2 pumps into 1. I supose the newer fuel pumps would be better. Can you sandwich those square fuel pumps?

The ignition uses the Ski-Doo crank hub. Machine the I.D of the XLT

flywheel to match the Ski-Doo hub and bolt them together. Make the

timing work out before you drill the XLT flywheel. I found that the XLT

ignition had a wee bit more advance in the mid RPM (3500-5000) to make

improved power there. The XLT ignition is all there.

The ignition uses the Ski-Doo crank hub. Machine the I.D of the XLT

flywheel to match the Ski-Doo hub and bolt them together. Make the

timing work out before you drill the XLT flywheel. I found that the XLT

ignition had a wee bit more advance in the mid RPM (3500-5000) to make

improved power there. The XLT ignition is all there.

At this date, 03/20/2006, a sleeve costs about $90.00 and a piston is about $150.00. $720.00 for those parts alone. The Ross pistons in my hemi didnt even cost $100.00 each, seems like the snowmobile guys are getting everything they can out of it.

Shipping weight on this will be in excess of 100 lbs.

I just don't have the time or the desire to do this snowmoblie stuff anymore. So my loss is your gain.

WOW this thing would make serious power. The more I work on this page the more I want to keep this and build it. I don't want to snowmobile anymore, so where would I put it?. Some sort of drag bike? 4wheeler? ??????? If this doesn't sell, perhaps I will build it, using 72mm, 80mm or 84mm pistons. The 72mm would bring it in at 780cc so you could race 3 classes; 800, 1000, and open.

| |||||||||||||||

| |||||||||||||||

|

| |||||||||||||||

| bore | application | stock stroke | displacement | comments |

|---|---|---|---|---|

| 57.5mm | Vespa Malossi Man their cylinder is Swiss Cheese | 51mm | 499cc | Has windows around wrist pin to evacuate under piston. |

| 63mm | 1978 340 RV F/A | 54mm | 598cc | early RV engine too small to make transfers work? |

| 67.9mm | ATK 260 1995 | 69.8mm | 695cc | Rotary Valve piston Rotax |

| 68mm | Yamaha YZ 250 1983-98 | 68mm | 697cc | Reed Valve check skirt for cut outs that weaken piston |

| 72.5mm | 521 oversize | 64mm | 793cc | |

| 77mm | Crank Shop | 894cc | ||

| 81mm | ????? | 64mm | 990cc | |

| 85mm | Yamaha YZ 400/465 1975-82 | 70, 82mm | 1089cc | 18mm pin, reed, half moon cut away, bottom of skirt, heavy. |

| 87mm | Yamaha YZ 490 | 82mm | 1141cc | 18mm pin, reed, 89mm overbore, 1195cc |

| 92.25mm | KTM 495 1981-84 | 74mm | 1284cc | 1981 piston port, ?wrist pin |

| bore | application | comments |

|---|---|---|

| 54mm | Can-Am 125 MX 1974-87 | |

| 62mm | Can-Am 175 MX1-3 1975-> | |

| 64.5mm | Can-Am 200 1987 | |

| 67.75mm | ATK 250 1995 | |

| 67.9mm | ATK 260 1995 | |

| 72mm | Can-Am 250 MX1-3 1975-> | |

| 74mm | Can-Am 250 MX4-6 | |

| 76mm | Can-Am 250 MX | |

| 80mm | Can-Am 320 1984, stock stroke 64mm, 965cc | Should be 18mm wrist pin, sleeves and pistons from this would simplify the whole deal. |

| 84mm | Can-Am 370-400, ATK 406, stroke 66/72mm 1064cc | Reed valve, ATK lists 18mm wrist pin for 1988-96, pn 420-292-075 |

| 85mm | Can-Am 500ASE | 20 mm wrist pin? |

| 54mm | Ski-Doo TN'T 250 RV F/A 1975- | |

| 63mm | Ski-Doo TN'T 340 RV F/A 1975- | |

| 65mm | Ski-Doo 440 type 453 | |

| 67.5mm | Ski-Doo 440 type 454 | |

| 69.5mm | Ski-Doo 463 type 467 | |

| 69.5mm | Ski-Doo 779 | Reed valve. Cut away skirts? |

| 70.5mm | Ski-Doo 809 | Reed valve. Cut away skirts? |

| 72mm | Ski-Doo 521 type 536, 537 | |

| 76mm | Ski-Doo 583 type 582, 583; 617 type 643 | |

| 78mm | Ski-Doo 670 type 669, | 20 mm wrist pin |

| bore | application | comments |

|---|---|---|

| 79.4mm | Precision Products 583 big bore | Wiseco forged piston w/L ring |

| 71.9mm | Crank Shop pistons listed below use the 18mm wrist pin. Visit their PISTON page. | |

| 72.15mm | Crank Shop | |

| 73.4mm | Crank Shop | |

| 76.5mm | Crank Shop | |

| 77mm | Crank Shop | |

| 79.4mm | Crank Shop | |

| 79.65mm | Crank Shop | |

| 79.9mm | Crank Shop ?80mm? | |

| 83.87mm | Crank Shop ?84mm? | |

If you think this is a wild project check out the 6 cylinder on the Union Bay picture page it is near the bottom.