.

JVX Racing makes an adapter plate to hook a 518 to a big block. It is pictured on page 13 of their PDF catalog. I believe it's over $500.00. This adapter comes with a special (required) flexplate, and has a notch cut in the bellhousing for starter clearance.

So I scrounged up a Ford E4OD and built an adapter to hook it to a big block, pictured at left. I have not made the flywheel adapter yet. Now I have misgivings. I want to go all Mopar......

So I scrounged up a Ford E4OD and built an adapter to hook it to a big block, pictured at left. I have not made the flywheel adapter yet. Now I have misgivings. I want to go all Mopar......

I have a Baumann TCU control for the E4OD, supposedly they have programing to work with the new Dodge E, or FE type transmissions.

One thing is certain, the old 727 was far and away the strongest,and lightest, 3 speed automatic, but adding the OD on the tailshaft has become a limiting factor.

Overdrives are not the most efficient method to gain lower cruising RPMs. The least friction would be to use taller rear end gears and have a direct drive high gear. Oh wait a minute Doug Nash made his old 4+1 that way didn't he, see the Richmond Gear site. Check out the Baker DD6 for the Hardly a Davidson.

These simple lever drawings demonstrate the force needed to move a 2000lb object.

Is there is enough material around the tail housing to bolt on the 518 OD unit and supply it with oil passages?

The A345 case might make it easier to put a big block in a new Ram 1500. Perhaps I can find a picture of the back of the case, to compare oil passages.You can barely make out the pattern of the gasket, pictured to the right.

I doubt there would be oil passages that allow for a lock-up converter. If Bill Jenkins could use epoxy to build up intake ports maybe that could work here too. Or you could have overdrive with out lockup.

I have not seen one of these transmissions in years though.

This thing is awfully ugly

The difference between the compounder and the overdrive is actually quite simple. You just hold, or drive, different pieces, of the planetary gear set, to change from underdrive,overdrive or reverse. Visit the Gear Vendors Over/Underdrive page.

There is plenty of verbage about these old clutchflite type trannys on the internet. There were 4 different transmissions that were modified for the use of a regular clutch. The MoPar 727 Torqueflite, the Ford C6, the Turbo400, and the old TurboHydraMatic (4 speed, "dual range").

I have a Lakewood Scattershield, Hayes Flywheel, and some other manual trans stuff.

Maybe a hydraulic release bearing, to do away with the fork and linkage?

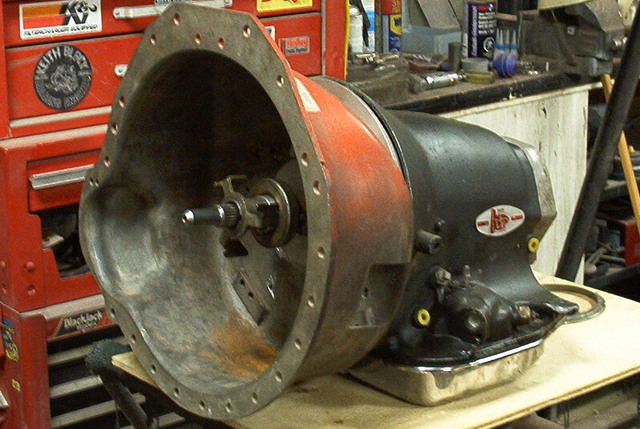

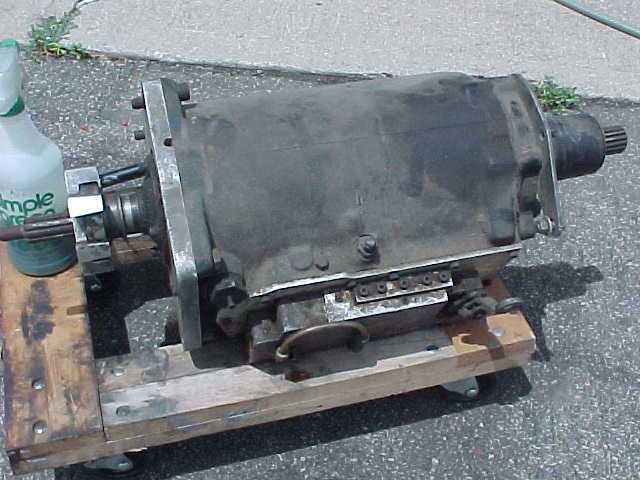

These pictures are someone else's. I stole them off the net. They will have to suffice until I can find a ClutchFlite of my own. The first one is a regular long output shaft. The next 2 are of a shorty output shaft.

These pictures are someone else's. I stole them off the net. They will have to suffice until I can find a ClutchFlite of my own. The first one is a regular long output shaft. The next 2 are of a shorty output shaft.

B&M and Fairbanks sold these kits. The Clutchflite could be purchased for use behind GM, FoMoCo, or Chrysler engines. The basic difference would be in the lenght of the input shaft. A Chrysler bell housing is roughly 1" deeper than the other guys. Also in the days before scattershields B&M sold a clutchflite that used the existing bellhousing of the 727 tranny.

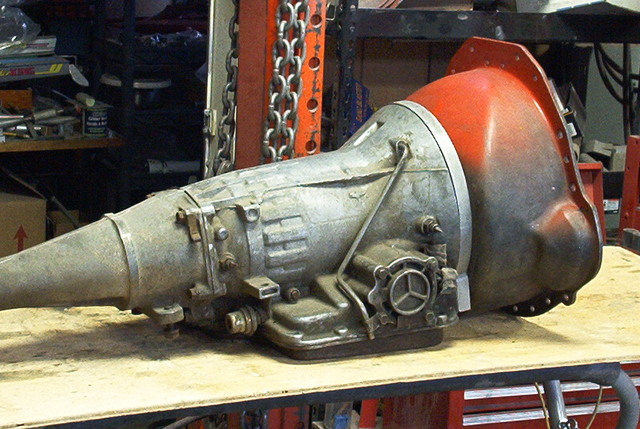

This picture is someone else's I took it from the

H.A.M.B forum. This one looks like it is attached to a Ford bellhousing.

This picture is someone else's I took it from the

H.A.M.B forum. This one looks like it is attached to a Ford bellhousing.Not much spline for engagment in the clutch disc. Certainly not enough for a dual disc clutch. When I had a big block and 4 speed the clutch always slipped when I power shifted, even with massive spring pressure. Then I bought a metalic disc, that cured the slip, but it always chattered when engaging, and wore out the flywheel and pressure plate in no time at all.

When I was young and foolish I built a full tilt, reverse pattern, manual shift 727. With 160+ lbs line pressure, and all the badest hardware available at the time. It shifted so hard that it chirpped the tires into 2nd at idle. It even blew the end out of a valve body passage (that was my first experience with a "trans brake", at about 90 MPH). All the clutches were stripped of their lining after that maneuver.

What would that be like with out the cushion of the hydraulic coupling (torque converter)? would you want to start with a stock grand ma's valve body? Perhaps you could keep the 1-2 accumulator functioning, and find some other way to firm up the 2-3 shift. Once I drilled holes in the drum the allow oil trapped between the discs to escape, AND to help push the band off the drum. I have seen other mods that slow the apply oil to the high gear clutch, allowing the band to release before the clutch applies.

What would that be like with out the cushion of the hydraulic coupling (torque converter)? would you want to start with a stock grand ma's valve body? Perhaps you could keep the 1-2 accumulator functioning, and find some other way to firm up the 2-3 shift. Once I drilled holes in the drum the allow oil trapped between the discs to escape, AND to help push the band off the drum. I have seen other mods that slow the apply oil to the high gear clutch, allowing the band to release before the clutch applies.The old valve bodies could be made to shift with brutal force into 2nd, but 3rd always seemed soft. Supposedly the Turbo Action, Cheetah, valve bodies fixed that.

Would a clutchflite really be any worse than a slick shifted 4 speed? Or a clutchless 4 speed? Or a Lenco? Check these web sites,Libertys Clutchless, Lenco. Judging from the prices I see on those pages, an old clutchflite seems like a pretty good idea.

The sliders (collars) on the left show every other tooth or spline removed. This is a slick shift set for an A-833 Chrysler 4 speed. I have read that these parts created a "land office parts business".

The sliders (collars) on the left show every other tooth or spline removed. This is a slick shift set for an A-833 Chrysler 4 speed. I have read that these parts created a "land office parts business".

I believe this is the begining of the aftermarket clutch autos. The 50s-60s GM Hydra-Matic dual range 4 speed auto. Standard ratios were 3.82, 2.63, 1.45, 1.00. Comercial vehicles used 4.08, 2.63, 1.55, 1.00 ratios.

I believe this is the begining of the aftermarket clutch autos. The 50s-60s GM Hydra-Matic dual range 4 speed auto. Standard ratios were 3.82, 2.63, 1.45, 1.00. Comercial vehicles used 4.08, 2.63, 1.55, 1.00 ratios. These transmissions had a fluid coupling rather than a torque converter, there would have been no torque multiplication and a tremendous amount of "slippage". So now we see the reason for adding the clutch.

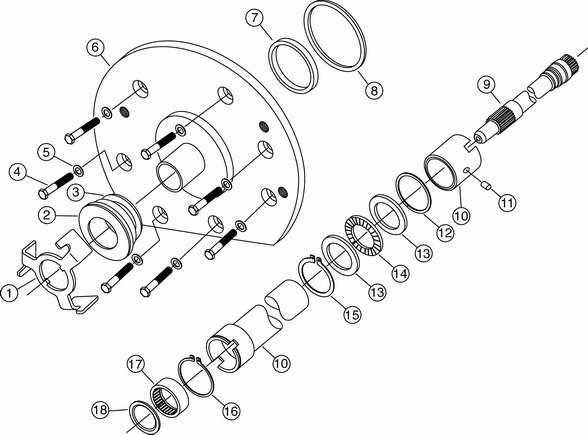

The spider engages the fingers on a Borg and Beck, or a Long style pressure plate, and drives the stock automatic oil pump. This spider looks like a 6 finger set up, it probably was used behind a CrowerGlide type of clutch. Yes there were a few home brewed units with an external oil pump, but the "real" ones were self contained.

A turbo 400 set up for a clutch.

A turbo 400 set up for a clutch.

The photo at left shows a c6 set up for a clutch.

The photo at left shows a c6 set up for a clutch.