3 CYLINDER - Dual Rotary Valve

page counter

3 CYLINDER - Dual Rotary Valve | page counter |

| |||||||||||||||

| |||||||||||||||

|

| |||||||||||||||

These 2 photos are mock ups, You choose the bore size and make it what you want. Just remember it has 18mm wrist pins.

These 2 photos are mock ups, You choose the bore size and make it what you want. Just remember it has 18mm wrist pins.

The POLAR crankcases cost $1500.00. The Crank Shop sells a case like this for $2100.00. These cases have never been assembled, they are NEW. They are .400" taller than stock, to make room for the 120°

intake spacing. You can visit my

porting page to see the advantages of the rotary valve over the reed valve.

The POLAR crankcases cost $1500.00. The Crank Shop sells a case like this for $2100.00. These cases have never been assembled, they are NEW. They are .400" taller than stock, to make room for the 120°

intake spacing. You can visit my

porting page to see the advantages of the rotary valve over the reed valve.

On a 2 cylinder the ports are 180° apart, on a horizontal

line. To get the 120° spacing the ports are squeezed toward each other at

the top. This necessitates a taller case and a shorter cylinder.

On a 2 cylinder the ports are 180° apart, on a horizontal

line. To get the 120° spacing the ports are squeezed toward each other at

the top. This necessitates a taller case and a shorter cylinder.

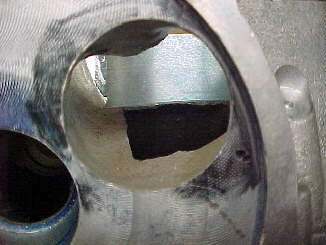

These next 2 pictures show the proximity of the ports to the RV edge. The

distance is roughly 1/8".

These next 2 pictures show the proximity of the ports to the RV edge. The

distance is roughly 1/8". Some people are concerned with this dimension, but just like the 2 bangers it can have a brass wear plate added if it wears.

Left, POLAR supplies an RV cover machined from flat plate.

Left, POLAR supplies an RV cover machined from flat plate. Right,

the extra, semi finised RV cover.

The crankshaft has been assembled. The 583 connecting rods have 18mm wrist pins.

The crankshaft has been assembled. The 583 connecting rods have 18mm wrist pins.

The assembled a crank.

The assembled a crank.

The head is made from 2- heads welded together. This head has been surfaced.

The head is made from 2- heads welded together. This head has been surfaced.

Left,

2 RV shaft assemblies with water pump impellers.

Left,

2 RV shaft assemblies with water pump impellers. Right, 3 NEW boots for 44mm Mikuni carbs, 3 exhaust flanges.

Left, gaskets, seals and o-rings

Left, gaskets, seals and o-ringsRight, fuel pump made by sandwiching 2 pumps into 1.

The ignition uses the Ski-Doo crank hub. Machine the I.D of the XLT

flywheel to match the Ski-Doo hub and bolt them together. Make the

timing work out before you drill the XLT flywheel. I found that the XLT

ignition had a wee bit more advance in the mid RPM (3500-5000) to make

improved power there. The XLT ignition is all there.

The ignition uses the Ski-Doo crank hub. Machine the I.D of the XLT

flywheel to match the Ski-Doo hub and bolt them together. Make the

timing work out before you drill the XLT flywheel. I found that the XLT

ignition had a wee bit more advance in the mid RPM (3500-5000) to make

improved power there. The XLT ignition is all there.